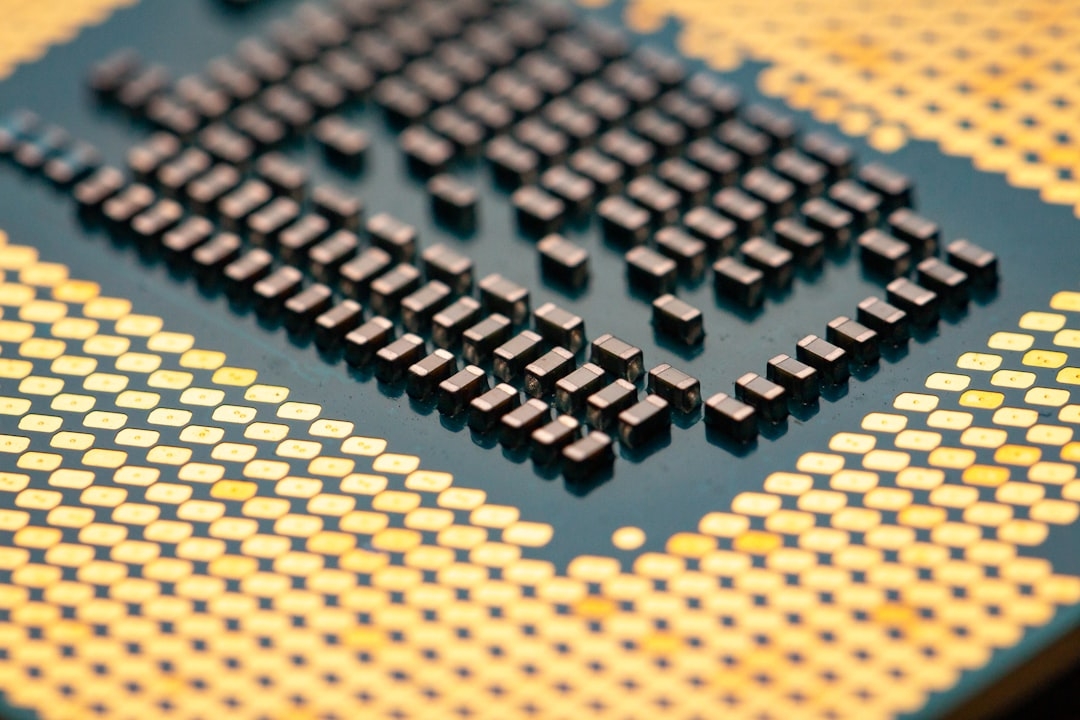

In an effort to enhance semiconductor production domestically, Taiwan has committed to investing a staggering $250 billion in the United States. This move follows a recently struck trade deal between the two countries, aiming to support and expand the US semiconductor manufacturing industry.

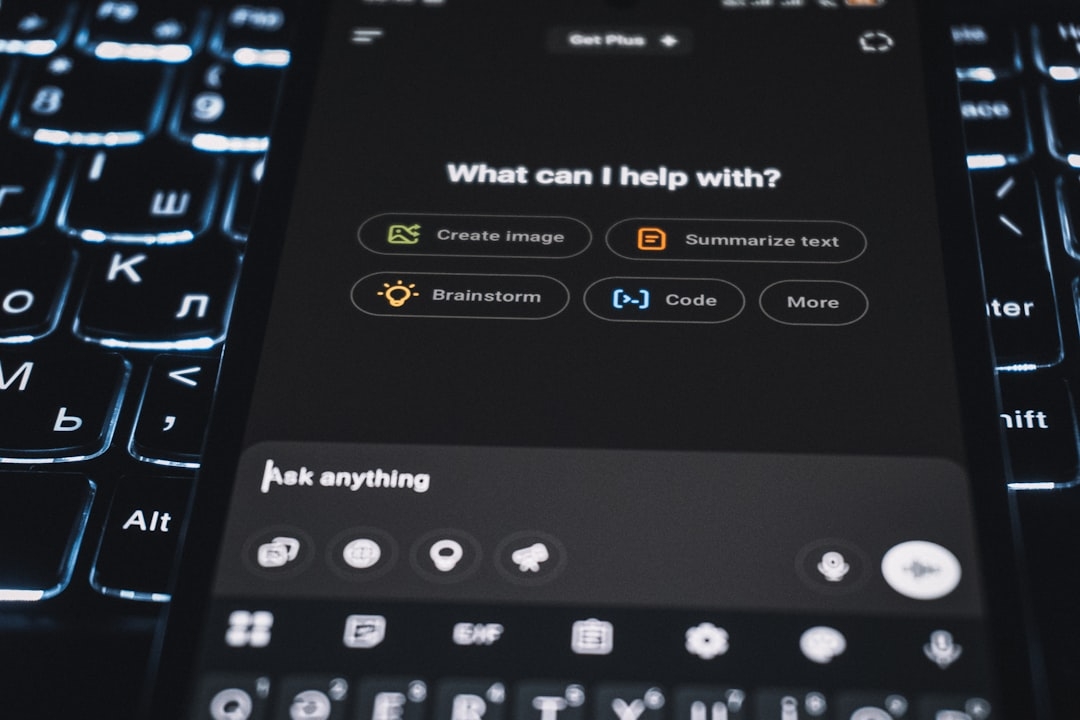

Semiconductors, often described as the backbone of modern electronics, power everything from smartphones to complex artificial intelligence systems. With growing global demand and recent supply chain challenges, this investment highlights the strategic importance governments place on chip manufacturing.

What Does Taiwan’s Investment Mean for US Semiconductor Manufacturing?

Taiwan's investment indicates a major shift in the chipmaking landscape. As one of the world’s leading producers of semiconductors, Taiwan’s top industry players—such as TSMC (Taiwan Semiconductor Manufacturing Company)—are highly capable of advancing technology and production scale.

This fund will support building new fabrication plants (fabs) and upgrading existing facilities across the US. It’s expected to generate a multiplier effect, including technological innovation, job creation, and enhanced supply chain security.

How Does Semiconductor Manufacturing Impact Technology and Economy?

Semiconductor manufacturing involves producing tiny chips crucial to electronic devices. These chips are created through complicated processes in fabs, which require precision machinery, clean rooms, and specialized materials.

The US currently relies on international sources for a significant portion of its chip supply, which poses risks during geopolitical tensions or global emergencies. Increased local manufacturing will reduce dependency and improve resilience.

Key Benefits of Taiwan’s Investment:

- Boosting domestic production capacity, reducing import reliance.

- Advancing chip technology through joint innovation efforts.

- Creating thousands of high-tech jobs across manufacturing, R&D, and supply chains.

- Strengthening US-Taiwan trade relations and strategic partnerships.

Why Is There a Need for a Trade Deal Between the US and Taiwan?

The semiconductor industry is highly integrated and complex. The US benefits from access to Taiwan’s advanced chipmaking know-how, while Taiwan gains from investment opportunities and expanding its footprint in the US.

The trade deal facilitates smoother cooperation, reduces tariffs, and encourages shared standards—critical for managing supply chain risks and accelerating production efficiency.

What Are Common Misconceptions About Increasing Domestic Semiconductor Production?

Some believe localizing semiconductor production instantly solves supply chain problems. However, building and ramping up fabs is a multi-year process requiring steady investment, skilled labor, and technological adaptation.

Additionally, high-end chip manufacturing demands extreme precision and constant innovation. Scaling production without compromising quality presents constant challenges.

Comparison of Semiconductor Production Aspects

| Aspect | International Manufacturing | Domestic US Manufacturing |

|---|---|---|

| Production Scale | Massive, established | Growing but limited |

| Technological Level | Leading-edge fabs | Developing high-end capabilities |

| Supply Chain Dependence | High, risk of disruption | Lower, more secure |

| Investment Cost | Spread globally | High upfront in new fabs |

How Will This Investment Affect Future Technology Development?

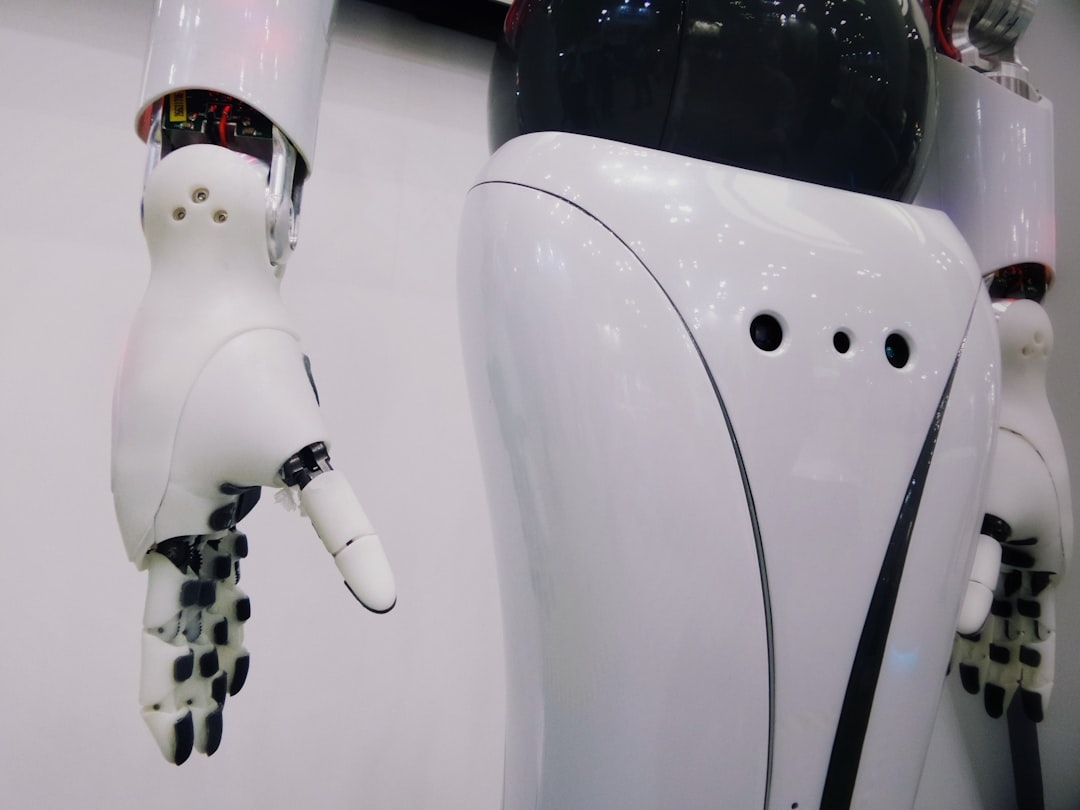

By investing heavily in US semiconductor capacity, Taiwan helps to ensure that America remains competitive in cutting-edge technology fields such as artificial intelligence, 5G networks, and quantum computing.

This collaboration paves the way for advancements that can otherwise be delayed by chip shortages or geopolitical instability.

What Challenges Remain Despite This Investment?

Despite the optimistic outlook, practical challenges include:

- Building skilled local workforce fast enough to meet production demand.

- Keeping up with rapid technological changes in semiconductor processes.

- Maintaining cost efficiency amid increasing production complexities.

- Ensuring supply chain components (like raw materials) are also secured domestically or from trusted partners.

These hurdles require ongoing attention beyond just financial investment.

Conclusion

Taiwan’s $250 billion investment represents a transformative opportunity for US semiconductor manufacturing, offering greater production independence and innovation potential. It exemplifies how international partnerships can address critical technology supply issues.

However, success depends on navigating manufacturing complexities and workforce development effectively. The partnership highlights the need for sustained effort and coordination between governments and industry leaders.

Test your understanding: Explore your local electronics or tech store and identify at least three everyday devices that rely on semiconductors. Reflect on how supply disruptions could affect these products’ availability or cost over time.

Technical Terms

Glossary terms mentioned in this article

Comments

Be the first to comment

Be the first to comment

Your opinions are valuable to us